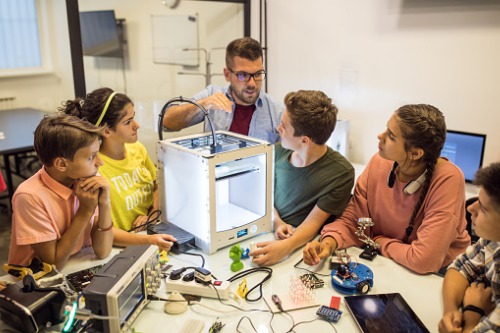

While 3D printing is proving to be highly beneficial for teaching and learning processes in the classroom, poorly managed print devices can open schools up to various risks and vulnerabilities.

A study commissioned by Y Soft found that 87% of educators are restricting student access to 3D printers due to a lack of management resources and skills.

Schools’ main security concerns included students printing when not permitted and interrupting or cancelling projects already underway, unprotected access to the printer and unmonitored printing.

Adam O’Neill, managing director, Y Soft Australia, said it’s critical school administrators implement strong access management policies to ensure 3D print solutions are used responsibly, safely, and cost-effectively, and can support learning needs to their full potential.

“Without an access management policy, principals can’t fully see the practical or financial outcome 3D print activity or make important decisions on how infrastructure can be updated or improved,” O’Neill told The Educator.

“Access management policies need to ensure 3D print technology is both safe and secure, while also used to its full potential.”

O’Neill said school administrators should select 3D printers specifically designed for schools to ensure student safety.

“School-specific 3D printers don’t expose students to high heat and moving parts, due to a fully enclosed the print chamber. 3D printers can also allow access via card swipes or user credentials, meaning staff don’t need to constantly monitor printers to prevent unsafe or unauthorised access,” he said.

“Lockable doors prevent students from accessing printers when they shouldn’t be; saving schools money that might otherwise be lost on energy, resources, and unnecessary maintenance to replace missing or broken pieces.”

O’Neill said many of the challenges identified in the study can be solved with print management; the same print management schools use today for their paper printers.

“Strong print management software can require students and staff to use ID cards, or username/PIN credentials [or both] to access printers. This means schools can make printers available in open areas, maximising their potential,” he said.

“Beyond student safety, lockable doors on a 3D printer mean only the job owner can retrieve a 3D print when it’s finished, or cancel or pause print jobs. This solves the challenge of other students taking or interfering with other peoples’ print jobs.”

O’Neill said print management software also provides print activity and filament-use reports.

“Schools can use this to analyse and budget their use of consumables more efficiently and accurately. They can also identify peak printing times, or printers that aren’t used often, which can be relocated elsewhere,” he said.

“Managing 3D print technology more effectively gives principals valuable visibility and control over who is printing what, and when. This visibility lets principals make decisions around where to cut costs or improve 3D print capabilities.”